We got real tired of climbing a ladder through a 24"x36" hatchway to

get to Peggy's weaving studio, storage space and my drafting table.

We got real tired of climbing a ladder through a 24"x36" hatchway to

get to Peggy's weaving studio, storage space and my drafting table.

I really didn't want to lose any more space than neccessary on the main shop floor so we agreed to attempt a spiral stair.

Central support pipe, separate, slip-over tread support units, 2"x10"

un-planed plank treads, ca. 130" rise, 1-1/4 turns, 12 treads per turn,

ca. 28" treads, 61" opening in the upper floor.

The individual treads are 4" schedule 40 pipe segments a bit over 8"

long with a support bracket welded on. The bracket material is some

kind of m/s machine housing panel from the scrap yard, slightly less

than 1/8" thick. The advantage to this approach is that each unit can

be built in a jig on the bench —— no overhead

welding, no trying to get unreachable bits alignned properly.

The bracket material was 24"x36" so I had it sheared into 24"x9" rectangles. The guys with the big break couldn't bend them up to the desired shape without distortion to I had them do this:

Then I welded the sheared-off piece back on to form the bracket. This

automatically comes out to make a right-angle bracket if it's put on

edges up.

Then I welded the sheared-off piece back on to form the bracket. This

automatically comes out to make a right-angle bracket if it's put on

edges up.

The tread units slide over a central 3-1/2" OD steel pipe that is bolted

at the bottom with concrete anchors and braced in two directions at

the top with HSS braces. The pole stands free while the treads are

dropped on. One brace then clamps to the pipe and the other is

attached with a socket and set screw. Having two parts makes it much

easier to put the brace in place from a ladder without a helper. After

everything is in place, the setscrew joint is welded.

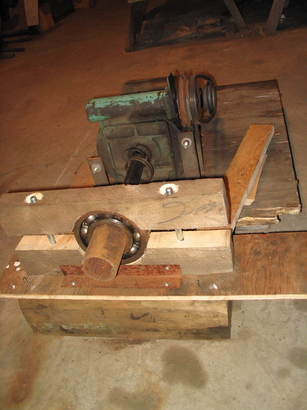

The central pole is 3-1/2" OD and 1/2" thick, some kind of extra-heavy

duty steam (?) pipe for oil drilling with stupendous pressure and

torque specs. Since I'm not a wizard welder, I wanted a real nice

joint when I welded two pieces together to get the full height

required. So I jiggered up this motor, gearbox, bearing and collet

affair to rotate the piece of pipe at ca. 10 RPM. With the other end

of the pipe in a chain-and-roller sling, I could just sit there with

the grinder on the metal while the pipe rotated and get a beautiful

bevel for a full-thickness weld on the 1/2" thick pipe.

The central pole is 3-1/2" OD and 1/2" thick, some kind of extra-heavy

duty steam (?) pipe for oil drilling with stupendous pressure and

torque specs. Since I'm not a wizard welder, I wanted a real nice

joint when I welded two pieces together to get the full height

required. So I jiggered up this motor, gearbox, bearing and collet

affair to rotate the piece of pipe at ca. 10 RPM. With the other end

of the pipe in a chain-and-roller sling, I could just sit there with

the grinder on the metal while the pipe rotated and get a beautiful

bevel for a full-thickness weld on the 1/2" thick pipe.

First four treads are in place. Tread #4 is anchored to the wall for

added stability. I worried that as the treads were lowered on, while

there was no support at the top of the pipe, things might get out of

balance and that 10' lever arm might lever the anchors out of the

concrete floor. So I got this wall attachment in place before treads 5

to 15 were dropped onto the free-standing pipe.

First four treads are in place. Tread #4 is anchored to the wall for

added stability. I worried that as the treads were lowered on, while

there was no support at the top of the pipe, things might get out of

balance and that 10' lever arm might lever the anchors out of the

concrete floor. So I got this wall attachment in place before treads 5

to 15 were dropped onto the free-standing pipe.

Tread, braces and landing in place. Three additional 1/8"x2" hangers

at 3, 6 and 9 o'clock. No hand rail yet. I hope to use some old

hawser but haven't figured out how to do it yet. As a temporary

safety measure, there's a vertical 2x6 (not shown) in the one place

where a misstep could be fatal.

Tread, braces and landing in place. Three additional 1/8"x2" hangers

at 3, 6 and 9 o'clock. No hand rail yet. I hope to use some old

hawser but haven't figured out how to do it yet. As a temporary

safety measure, there's a vertical 2x6 (not shown) in the one place

where a misstep could be fatal.

So there it is.

One interesting point: I didn't make any attempt to get the 4" pipe

segments perfectly aligned with each other on the 3-1/2" pipe. The 4"

pipe segments are 3-9/16" ID giving 1/16" clearance. If the tread units are

allowed to cock by that much, all the weight of the user is taken by

the pipe itself, not by the welds. The only forces on the welds that

join the segments is horizontal. That's a pretty small shear force on

the welds. So a few small welds between segments is sufficient to

keep the treads from rotating.