Eighteen ga. magnet wire is mounted on a spool made from lath, dowel and rubber bands, equipped with a foam-rubber friction brake and mounted on the skeleton of a weight-lifting bench.

Wire feeds through the mouthpiece from a candle stick-style (or maybe even older) phone, over wire pulleys from the Michelin wire mill scrap heap and onto the bobbin.

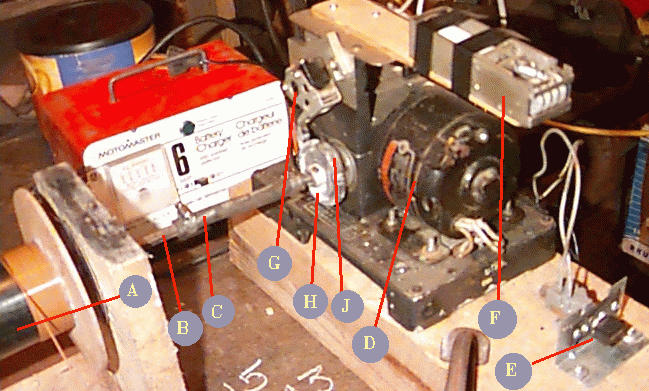

Bobbin (A) from 2" PVC pipe and Masonite, is mounted on temporary hubs made from toy truck wheels, 16 ga. punch plugs and bearing parts from a supermarket roller conveyor. It's turned by the hex shaft (B) running in ball bearings also from the roller conveyor. The shaft (B) is coupled to the navy surplus gear motor (D) with neoprene fuel line (C). Motor is 110V with a switch (E) from a scrapped data-tape drive.

The 4-digit electro-mechanical decade counter (F), from some 100-year old telco gear (?), is powered by the battery charger and triggered by a navy surplus micro-switch (G) which is in turn tripped by the plastic gear (H) from a laser printer. The latter has been converted to a cam by the addition of a lump (J) of butyl rubber caulking strip.

Seems to work fine. Had to add another hose clamp to the rubber coupling (C) to keep it from slipping on the gear shaft. And it seems almost impossible to keep the wire laying down smoothly in uniform coils without a mechanical device. However, it made up a 1600-turn coil in a few minutes.