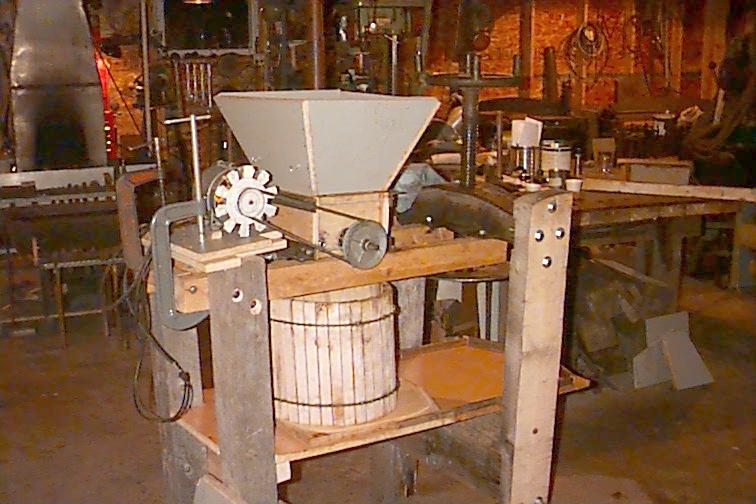

I had the screw and cast iron beam for years but one horn was broken off the wheel and fixing it seemed like a chore. Finally, when all our old apple trees bore heavily in the same year, I figured out how to fix it without risking the casting. Now that wasn't so hard, was it? Mmmpf.

So then I toured around, checking out antique presses. A hundred years old or more, they were all hand-cranked but I picked up other clues and this is what came out.

Motor from a washing machine, bearings a friend salvaged from the engine room of an ice breaker (!), miscellaneous bits. A wood-butcher friend sawed out all the little uniform maple sticks for the basket and I made up the bands.

The deck and the panel the basket sits on are that shiny-coated kind of fancy finish plywood. When the basket is full of pomace, the panel slides easily over under the screw with a push from a stick.

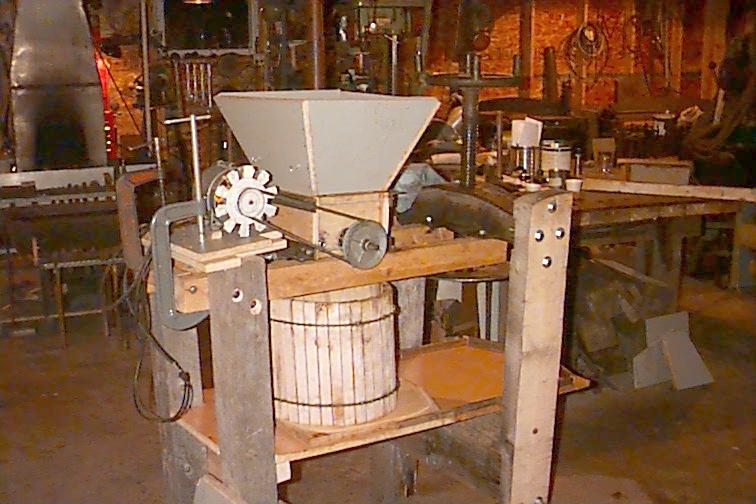

The only hard part was the pulper itself.

The rotor is a piece of medium-weight 4" steel pipe with plywood plugs J.B. Weld-ed in each end and metal flanges with set screws bolted to the plywood to hold the shaft. The 4 blades are 1/2 x 1/2 x 1/8 angle, opened up a bit more than the original 90 deg, sharpened on one edge, some teeth cut in with a ziz wheel and welded to the rotor.

The only part that isn't obvious is a curved plate next to the rotor that wobbles in such a way that when chunks of apple are slammed against it by the blades, its lower end mashes chunks that are half-way past the rotor. Copied from an antique press. It's not clear if it really makes any difference or not.

Since these photos were taken, the bearings (which tended to get full of pomace) have been replaced by proper pillow block bearings outside the plywood pulper chest, the C-clamps replaced by a hinged belt-tensioner affair, an electric switch added.

Figuring out the geometry to saw baffles to fit the angled hopper sides was too hard so the hopper is just a hopper and doesn't have baffles. As a result it has to have a weighted cover when operating or it fires apples 30' across the shop. Lift the cover, quickly throw in 2 or 3 apples and bang it shut. (There's still the occasional high-velocity escapee.) The motor doesn't have the gumpties to start under load if I just dump in a peck of apples before starting it.

Getting between a gallon and a gallon and a half to the bushel from unsprayed apples from both aged trees and younger volunteers that have grown up in the last 30 years.